Scaling up synthetic biology – lessons from Singapore

Singer Instruments’ partnership with the Singapore Consortium for Synthetic Biology

Synthetic biology in the age of AI

Now is a pivotal time in the quest to engineer biology. Precision lab automation combined with powerful new AI technologies have potential to vastly accelerate the synthetic biology ‘design-build-test-learn cycle’.

However, while AI dramatically accelerates the ‘design’ phase, it requires a corresponding scale-up in screening capacity to efficiently build and test those designs. Otherwise the potential of generative biology risks remaining largely theoretical, trapped within computational models.

Bridging this gap requires a revolution in high-throughput screening, precision robotics, integrated data management systems, and standardised workflows, all powered by lab automation.

Singapore has been instrumental in bringing forward solutions, driving more than a decade of state investment into initiatives designed to deliver automation solutions tailored to the specific needs of synthetic biology.

A rising star in the bioeconomy

Singapore’s ambitions to become a major player in the field of synthetic biology took a leap forward with the establishment of SynCTI in 2015, aimed at developing foundational technologies in synthetic biology and seeding the next generation of highly skilled researchers.

Hosted by the National University of Singapore (NUS), SynCTI serves as a research hub for synthetic biology, providing a range of state-of-the-art robotic systems available to accelerate the R&D cycle and help synthetic biology startups get over the hurdle of reaching commercially viable scales.

Alongside this is the Singapore Consortium for Synthetic Biology (SINERGY), an initiative that has so far given rise to collaborations with more than 30 industry partners, including Singer Instruments. As generative biology continues to push the boundaries of design, collaborative approaches like this will be vital to bring forward intelligent and integrated automation solutions appropriate for the scale and complexity of today’s science.

Designing a next-generation colony picker

SINERGY is headed up by synthetic biology visionary Professor Matthew Chang, who approached Singer Instruments in 2016 with a proposal to partner in the development of a next-generation colony picker. Crucially, it needed the efficiency and precision to decode complex biology, coupled with the integrability and usability to scale discoveries from the lab bench.

“When we began collaborating with Singer Instruments, our primary focus was on addressing key challenges hindering the process of engineering biology for industry applications, such as engineering microbes for chemical production. Our number one objective was to enhance efficiency and precision in our laboratory workflows, particularly through the establishment of a biofoundry in NUS,” explains Professor Chang.

“We were keen on automating manual processes to increase throughput and streamline our operations, which could support high throughput processing of samples and screening, allowing us to handle a large volume of experiments efficiently. Setting up an automated workflow was crucial for us to achieve our goals, as it would not only save time but also ensure consistency and reproducibility in our experiments.”

The power of co-design in lab automation

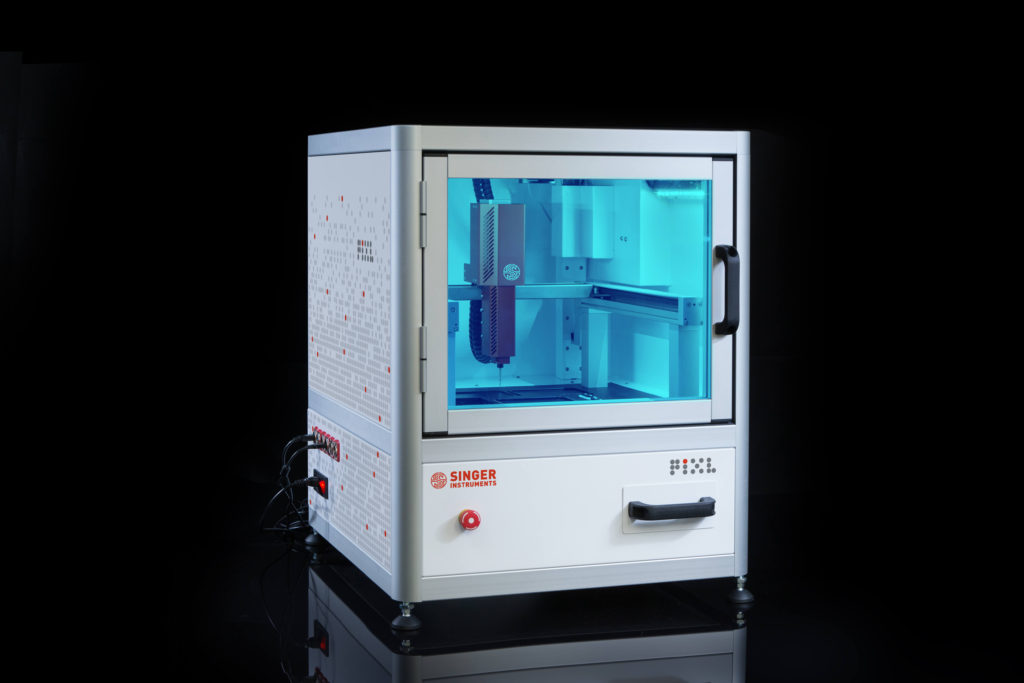

Singer Instrument’s scientists and engineers worked closely with SynCTI researchers, establishing a continuous learning-feedback loop that took PIXL from design to implementation within just two years of collaboration. The partnership led to significant improvements to the prototype, and in return, participating researchers benefited from having huge libraries of strains screened at low cost and in less time.

Reflecting on the value of the collaboration, Professor Chang says co-design has resulted in a colony picking solution uniquely positioned to meet market needs:

“Unlike traditional colony picking systems, PIXL’s advanced imaging technology allows for precise identification and selection of colonies based on various criteria such as size, shape, and colour. This level of precision minimises the risk of false positives or misidentification, ensuring the integrity of our experiments. Moreover, the unique pin-free colony picking system reduces the risk of contamination and saves us time in sterilising pins.”

It’s a model many larger lab automation companies struggle to replicate, says Harry Singer, chief executive of Singer Instruments:

“The lab automation market is changing. It’s more disruptive and there’s a faster technology churn. By entering into the spirit of collaboration, companies like ours are carving out specialist niches and driving innovation in line with market need. There aren’t many mainstream robotics companies that can pivot fast enough to do that.

“The reward for our customers is superior quality products and unique features that push performance boundaries. It’s exactly what is needed to grow the bioeconomy. And exactly what our technologies must achieve to delight our customers.”

“At the biofoundry, PIXL has unlocked new capabilities that were previously unattainable. For instance, we can now perform high-throughput screening of microbial colonies with unprecedented speed and accuracy. This has enabled us to explore a wider range of experimental parameters and scale up our screening efforts significantly.”

Associate Professor Matthew Chang,

Director of the Singapore Consortium for Synthetic Biology (SINERGY) and the NUS Synthetic Biology Centre for Clinical and Technological Innovation (SynCTI).

Leading synbio innovators told us they wanted the world’s most precise colony picker.

We delivered PIXL.