- Products

- Resources

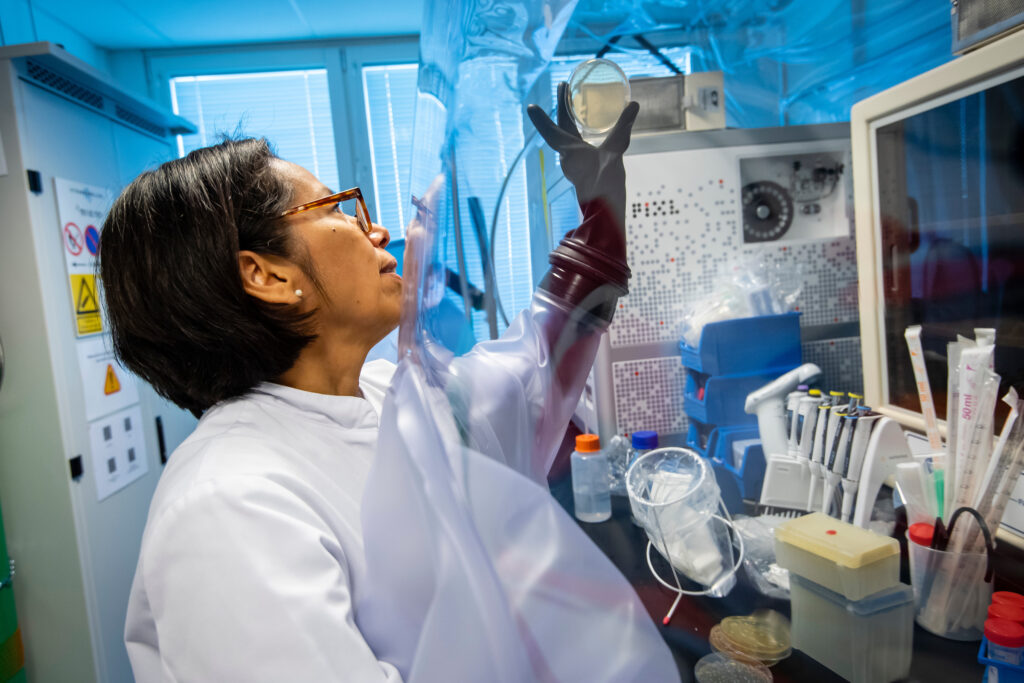

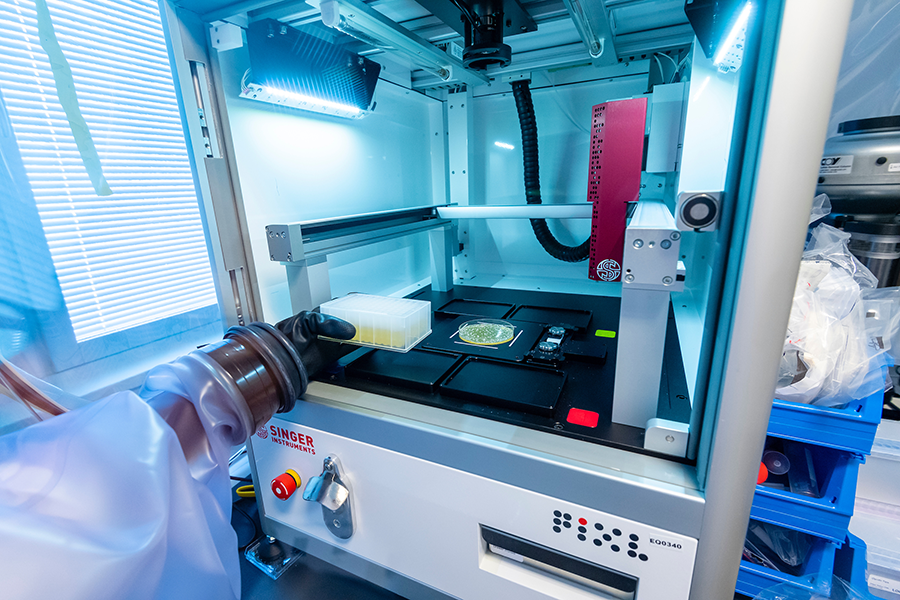

“At the biofoundry, PIXL has unlocked new capabilities that were previously unattainable. For instance, we can now perform high-throughput screening of microbial colonies with unprecedented speed and accuracy. This has enabled us to explore a wider range of experimental parameters and scale up our screening efforts significantly.”

Associate Professor Matthew Chang,

Director of the Singapore Consortium for Synthetic Biology (SINERGY) and the NUS Synthetic Biology Centre for Clinical and Technological Innovation (SynCTI).

The rise of synthetic biology

Now is a pivotal time in the quest to engineer biology. Precision lab automation combined with powerful new AI technologies have potential to vastly accelerate the synthetic biology ‘design-build-test-learn cycle’. Taking these crucial next steps towards a sustainable bioeconomy now relies on synthetic biology innovators being able to de-risk and commercialise their products. Fundamentally this means scaling up experiments, not incrementally, but by orders of magnitude.

Singapore has ambitions to become a major player in the field of synthetic biology and has established the Singapore Consortium for Synthetic Biology (SINERGY) in part to help overcome this issue. SINERGY is hosted by the National University of Singapore (NUS) and headed up by synthetic biology visionary Professor Matthew Chang. A primary aim is to increase the cross-talk between synthetic biology researchers and engineers to promote access to cutting-edge technologies.

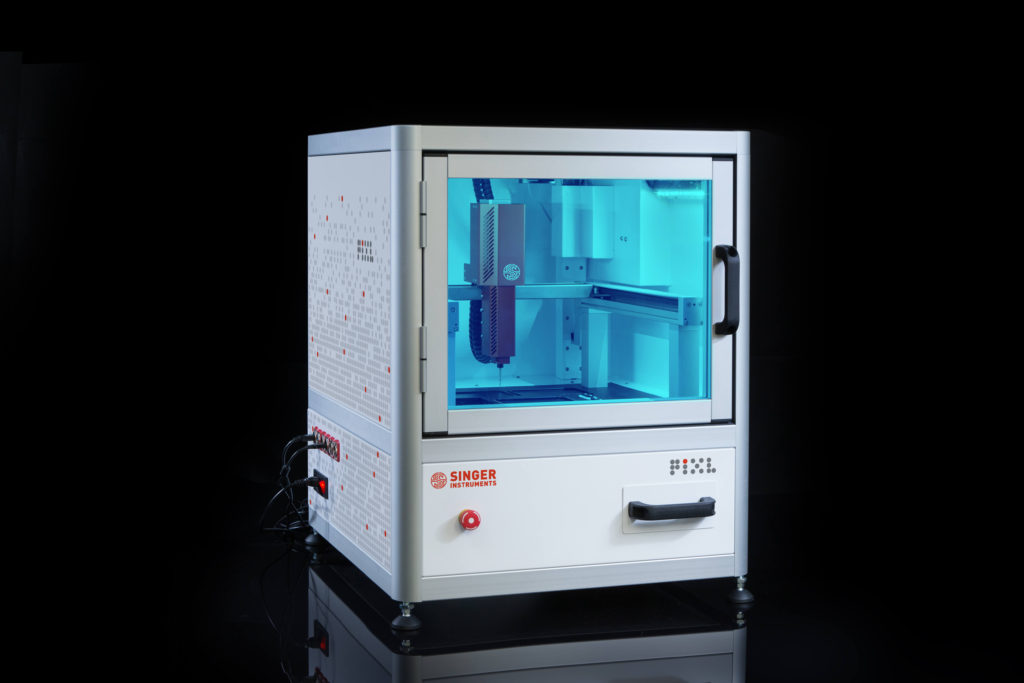

Designing a next generation colony picker

SINERGY approached Singer Instruments in 2016 with a proposal to partner in the development of a next-generation colony picker. Crucially, it needed the efficiency and precision to decode complex biology, coupled with the integrability and usability to scale discoveries from the lab bench.

“When we began collaborating with Singer Instruments, our primary focus was on addressing key challenges hindering the process of engineering biology for industry applications, such as engineering microbes for chemical production,” says Professor Chang.

As a key member of SINERGY, SynCTI serves as the NUS research hub for synthetic biology. SynCTI operates Singapore’s first biofoundry, housing a range of state-of-the-art robotic systems available to accelerate the R&D cycle and help synthetic biology startups get over the hurdle of reaching commercially viable scales. Singer Instruments is now among more than 20 industry partners directly collaborating with SynCTI to develop foundational technologies in synthetic biology.

“Our number one objective for the collaboration was to enhance efficiency and precision in our laboratory workflows, particularly through the establishment of a biofoundry in NUS,” explains Professor Chang.

“We were keen on automating manual processes to increase throughput and streamline our operations, which could support high throughput processing of samples and screening, allowing us to handle a large volume of experiments efficiently. Setting up an automated workflow was crucial for us to achieve our goals, as it would not only save time but also ensure consistency and reproducibility in our experiments.”

The power of co-design in lab automation

Our scientists and engineers worked closely with SynCTI researchers, establishing a continuous feedback loop that took PIXL from design to implementation in just two years .

Professor Chang says the collaboration has resulted in a colony picking solution uniquely positioned to meet market needs:

“Unlike traditional colony picking systems, PIXL’s advanced imaging technology allows for precise identification and selection of colonies based on various criteria such as size, shape, and colour. This level of precision minimises the risk of false positives or misidentification, ensuring the integrity of our experiments. Moreover, the unique pin-free colony picking system reduces the risk of contamination and saves us time in sterilising pins.”

It’s a model many larger lab automation companies struggle to replicate, says Harry Singer, chief executive of Singer Instruments:

“The lab automation market is changing. It’s more disruptive and there’s a faster technology churn. By entering into the spirit of collaboration, companies like ours are carving out specialist niches and driving innovation in line with market need. There aren’t many mainstream robotics companies that can pivot fast enough to do that.

“The reward for our customers is superior quality products and unique features that push performance boundaries. It’s exactly what is needed to grow the bioeconomy. And exactly what our technologies must achieve to delight our customers.”

The future of lab technology

Traditional model organisms like yeast and E. coli remain powerhouses for understanding basic cellular processes. Yet the goal of designing synthetic organisms for specific industrial applications is increasingly driving researchers to branch out into non-conventional organisms.

This is reflected in our customers, whose research now spans an increasingly diverse range of organisms and applications. From work to unpick the fundamentals of cellular biology through the Synthetic Yeast Genome (Sc2.0) and 1002 genomes projects. To resource-efficient bioprocesses developed from green algae and companies like SNIPR biome pioneering next generation antibiotics through gut-directed gene therapy.

To meet these unique challenges, Singer Instruments believes it’s vital that the future of lab technology is both flexible and reliable. It means labs can easily scale their experiments with the freedom to leverage the latest emerging technologies. But equally lab automation must be intuitive and easy-to-use. Empowering researchers to focus on the science ensures they aren’t held back by needing to develop specialist technical knowledge, simply to plan their workflows.

Singer Instruments has been serving the scientific community for 90 years. The science has changed, but the way we value our customers and faithfully channel this energy into developing unique products they can trust remains at the heart of our company. Our innovations are ambitiously setting new benchmarks for our industry. By measuring errors in parts per million we aim to bring forward a new era of precision microbiology. We couldn’t be more excited to be part of this evolving landscape and see where our future collaborations take us next!

SNIPR Biome is pioneering CRISPR-based microbial gene therapy with PIXL

Ensure your next colony picker offers the flexibility and scalability you need.

With PIXL Dark, your R&D team gains the flexibility you need now and the confidence that your workflows are futureproofed for scaling up.

The BioArt competition to celebrate the launch of PhenoBooth+ sparked creative microbiologists around the world.

Thank you to all of the labs that entered their BioArt.

Singer Instruments are pleased to announce the shortlist as follows:

- Horse and Cat by Erik Rodriguez, The George Washington University

- Microbes in Paris and Ada Lovelace by Rhizome Association

- ContiCollection by Hans-Peter Schmitz, University of Osnabrück

- Research in Microbiology: From Earth to the Great Unknown by Jean-Philippe Côté, The University of Sherbrooke

- FluoroPac and Pacmembert by Amritpal Singh, Imperial College Centre for Synthetic Biology

- E.coli-Rangoli by Balaram Khamari, Sri Sathya Sai Institute of Higher Learning

- Sunset at Cold Spring Harbor by Elena Ivanova, Institute of Molecular Biology, Mainz

- Pinky the gorgi by Kaveh Emami, Newcastle University

- Having fun with the Stinger and fluorescent yeasts by Matthias Meurer, Center for Molecular Biology at Heidelberg University

- Fractal by Marcus Walker, Imperial College Centre for Synthetic Biology

The Judges

[Best_Wordpress_Gallery id=”4″ gal_title=”PB+ judging panel”]- Harry Singer – Singer Instruments’ Managing Director and Physicist, did art at school for a bit

- Leo Davey – An award-winning, professional artist, keen to explore BioArt

- Grant Brown – Molecular Biologist, Professor at University of Toronto, enjoys teaching BioArt at Summer schools

- Ben Pollard – Software Manager, with no discernible talent for art, programmed the PhenoBooth+

- Jose Aguiar-Cervera – PhD student and PhenoBooth+ user who loves yeast

- Leah Ashley – Synthetic Biologist and Singer Instruments’ Asia-Pacific Manager, has a GCSE in art – don’t ask for her grade

The judging has now been held, stay tuned to see who the lucky winner is!

Which is your favourite plate?

[Best_Wordpress_Gallery id=”5″ gal_title=”PhenoBooth+ Comp”]

[hurrytimer id=”8423″]

Some of the entries received

[foogallery id=”8825″]

WIN A PhenoBooth+

Are you feeling creative? Enter an image of your most interesting plate for a chance to win a new PhenoBooth+, which includes a much higher resolution camera than the previous PhenoBooth, and now comes with a full five lighting channel setup.

You can create your BioArt whichever way you want, there are no limitations!

Maybe you’ve got a contaminated plate that is mesmerising – show it off to the world by entering it into the BioArt competition.

Perhaps your students have made BioArt by hand in the lab? Multiple submissions from your lab are allowed so you can get everyone involved!

Or have you made your BioArt using a robot? Let us know in the form below!

Entries must be submitted by the 7th of May so submit your entry before it’s too late!

If you see your BioArt in the frame above when the countdown comes to an end, you will be the lucky winner of a PhenoBooth+! Officially ending manual colony counting in your lab.

How to enter

To *enter the competition please submit your BioArt entry by email to this address contact@singerinstruments.com, fill in the form below and attach your file or simply submit your artwork via one of our social media platforms using the hashtag #SingerBioArt.

[forminator_form id=”8685″]

*Terms and Conditions

Entries should be submitted using the form above, through one of our social media channels using the hashtag #SingerBioArt or emailed to contact@singerinstruments.com and include the following details: your name, contact email address, your place of work, a name for your BioArt, and the organisms used.

The competition will close on the 7th of May at 10 pm (BST).

The winner will be selected by an esteemed BioArt judging panel who are looking for the most creative plate.

By entering this competition you agree that if you win, you are happy for your name and lab name to be used and you will provide Singer Instruments with a short write-up or interview for marketing purposes. The winner will be announced on Singer Instruments’ website and marketing channels and will be notified using the submission method provided.

By entering your images into the competition, you grant permission to Singer Instruments to use, reproduce and publicly display the image. Those who enter must have the copyright for all images entered. Singer Instruments may request higher resolution images as a condition of delivery.

The International Day of Women and Girls in Science is a stark reminder for us all how underrepresented women are in STEM-related fields.

Less than 30% of researchers worldwide are female according to UNESCO Institute for Statistics data.

Female enrollment globally onto STEM higher education courses is extremely low as only 35% of higher education STEM students are female.

Young girls are discouraged from studying a STEM discipline due to gender bias and gender stereotypes (1), which is one of the reasons why this international day is so important. We must empower girls through awareness and education to encourage more to pursue STEM careers.

Here is a list of incredible female scientists who became pioneers within their fields and shaped our world.

Rosalind Franklin (1920-1958)

When Franklin was just 15 years old she already knew she wanted to pursue a career in science. She was living her childhood dream when following her PhD she was offered the chance to be a research associate at King’s College London.

At King’s she worked on X-ray diffraction images of DNA which facilitated the discovery of the DNA helix by Watson And Crick. Photo 51 (see image) became vital evidence that revealed the DNA double helix structure. Unfortunately, Franklin died from ovarian cancer 4 years before Watson, Crick and Wilkins were awarded the Nobel Prize in Physiology or Medicine in 1962 for discovering the DNA double helix structure.

Despite the use of her X-ray crystallography observations to solve the chemical organisation of DNA the Nobel committee did not make posthumous nominations at the time.

However, Watson has himself suggested in an interview that to honour her contribution it would’ve been a good idea for Franklin and Wilkins to win the Nobel Prize in Chemistry.

Jennifer Anne Doudna (1964-Present) and Emmanuelle Charpentier (1968-Present)

Doudna and Charpentier are leading figures in the CRISPR Revolution for their work that was fundamental in developing CRISPR-mediated genome editing. In 2012 they proposed that enzymes from bacteria that control microbial immunity, known as CRISPR-Cas9, could be utilised for programmable editing of genomes. In 2020 they were awarded the Nobel Prize in Chemistry for developing the CRISPR-Cas9 method of genome editing.

Cynthia Kenyon (1954-Present)

In her early life, Kenyon worked on a farm before realising she wanted to study science to become a vet. She is now a pioneer in ageing research from her studies on the roundworm (Caenorhabditis elegans) which has demonstrated that genetic manipulation can change the process of ageing.

In 1993 Kenyon discovered that a single-gene mutation (DAF-2) doubles the lifespan of C. elegans and a second mutation in the gene for the transcription factor DAF-16 reverses this effect.

After 3 decades of research Kenyon’s final efforts are now focused on finding small molecules to allow disease-resistant youthful ageing in humans.

Janaki Ammal (1897-1984)

While growing up she watched as her sisters wed through arranged marriages. However, she followed her own intuition by embarking on a life of scholarship which began when she obtained a Bachelor’s degree at Queen Mary’s College (University of Madras) and was later awarded an honours degree in Botany. During this time women internationally were discouraged from higher education proving how fierce she was! In 1931 she became the first Indian woman to receive a doctorate degree in botany in the US.

As an expert in cytogenetics Ammal helped the Imperial Sugar Cane Institute in Coimbatore allowing them to develop and sustain their own varieties of sweet sugarcane. Her research helped determine which varieties of native plants to cross-breed with Saccharum to find a crop that was best suited for India’s tropical environments.

To honour her research in plant breeding, a variety of Magnolia was named after her: Magnolia Kobus Janaki Ammal.

Flossie Wong-Staal (1946-2020)

Flossie Wong-Staal was part of a team that first identified HIV was the cause of AIDS.

She became the first researcher in 1985 to clone HIV allowing scientists to understand how the virus evades the immune system. She finalised genetic mapping of the virus making it possible to develop testing for HIV. Her research contributed to the development of the blood tests we use to detect HIV.

Wong-Staal was quoted to say: “It adds to the joy of discovery to know that your work may make a difference in people’s lives”.

Towards the end of her brilliant career, she focused her effort on better understanding hepatitis C by working as the Chief Scientific Officer at Immusol, a biotechnology company, developing drugs to combat the disease.

She will be remembered as a ground-breaking researcher. Her methods are still practiced today to understand diseases such as Covid-19.

Hadiyah-Nicole Green

Hadiyah-Nicole Green had no aspirations as a child to become a scientist but now she is a multi-disciplinary physicist who specialises in targeted cancer therapeutics.

She admitted in an interview to The Scientist that she didn’t have a scientist as a role model in her life growing up, but she loved learning.

She earned her doctoral degree in physics at the University of Alabama becoming the second black woman and fourth black person to do so.

Her interest in developing a new cancer treatment became apparent after her aunt chose not to undergo chemotherapy after being diagnosed with female reproductive cancer and by watching her uncle, who developed oesophageal cancer, experience the unwanted side effects of chemotherapy.

Her aim, using her background in lasers, was to develop a treatment that targeted cancerous cells without damaging healthy ones.

She said during an interview “If we can see from a satellite in outer space if a dime on the ground is face up or face down, we should be able to do a better job of pinpointing the tumour and treating just the tumour and not the whole person.”

Her goal is to demonstrate the efficacy of the laser-activated nanoparticle treatment, which induces tumour regression by ~100%, in a variety of malignant tumour models.

This article gives a brief overview of the ground-breaking research these women have undertaken and the discoveries they have made which have shaped our world. If you enjoyed reading this article and would like to read more subscribe to our mailing list!

Singer instruments are delighted to announce we’ve won our first Tech South West Award! After attending the event virtually the team didn’t realise they had won an award until the next day. Congratulations to the team and thank you to the Tech South West team for hosting this event.

Each year Tech South West hosts an awards ceremony celebrating the success of the tech industry in the region. This year the event had to be held virtually due to Covid-19 restrictions however, still over 200 attendees gathered to celebrate what they’ve achieved this year. Singer Instruments were thrilled to be shortlisted alongside the best tech companies in the region for the second year in a row, yet had no expectations of winning an award. But we did just that!

Harry Singer our managing director explained “Six of us attended the ceremony. We watched everything. But none of us realised we’d won anything! I think we might have all been distracted by the banter in the social feed! The awards ceremony itself was so snappy and up-beat, blinking put you at risk of missing something. In fact, we didn’t even realise we’d won an award until the next day.”

“Massive thanks as ever to the Tech South West team. They’re doing a great job at connecting, celebrating and showcasing tech companies and growing the talent pool in our region. And it looks like they’ve got even more awesomeness in the pipeline for next year.”

Singer Instruments are proud to announce we’ve won our first Tech South West Award! We are really honoured by this recognition for our innovative programmes, our fantastic company growth and our tech success in the South West.

Congratulations to the entire Singer team for making this possible!

We are overjoyed to be announced as ‘Employer of the Year’ at the Somerset Business Awards. At Singer Instruments we develop world-class robots for biotechnology. Our products accelerate science in laboratories in over 50 countries, for customers like NASA, Cancer Research UK, and the top 50 universities in the World.

The Employer of the Year award is recognition of 4 years of hard work, specifically aimed at improving staff inclusivity, satisfaction, and retention:

‘Profit Share for Nerds’ is a Company bonus scheme, launched in 2016. 50% of profits above target are divided among all employees. This year, our staff are due to receive bonuses at 13% of their annual salary.

We launched ‘Equity for Nerds’ in 2018. As a recognised Government SIP scheme, this optional employee share options scheme gives employees a tax-efficient way to receive bonuses and make an investment that is currently growing at about 25%. Year one saw a 50% adoption rate, and half of Singer Instruments employees are now business owners!

Other notable initiatives include a program to increase salaries towards being nationally competitive; a transparent pay banding structure for fairness and to augment understanding of career progression; a program to increase holiday allowance by an extra day per year for the next 5 years.

Since the implementation of these initiatives, we have noted a marked improvement in staff retention from 75% to 91%.

We now perform above Health & Safety Executive (HSE) targets in all categories: Demands; Control; Managers’ Support, Peer Support, Relationships, Role, and Change. The HSE has recently showcased Singer as a case study in recognising and dealing with the prevention of workplace stress and related issues.

Our MD Harry Singer, 3rd Generation family-owner of Singer Instruments says: “Recruiting high-quality engineers, software developers, and biologists is difficult, especially when you’re based in a tiny little village like Roadwater. Over the years we’ve had to work extra hard to make Singer Instruments attractive enough to lure engineers from the likes of Red Bull Racing and managers away from BMW and Facebook. It’s really nice to get recognised as a great place to work, thanks very much to the Chamber of Commerce and Somerset Business Awards!”

At Singer, we believe in a healthy work-life balance, with staff encouraged to limit working hours from 9 to 5. The atmosphere is relaxed, attitudes are positive, and nobody wears a suit. We firmly believe that a strong focus on transparency, clear growth pathways, an inclusive strategy, and a shared rewards structure makes for a dynamic, buzzing atmosphere with engaged, happy teams who really look forward to coming into work on a Monday morning. Most of the time!

Fancy working at Singer Instruments?

If Singer seems like the right place for you or you are a keen intern looking for some experience, then please get in touch. We are always on the lookout for top talent.

Click here to see what positions are currently available.